Metal Spinning & Custom Metal Forming Manufacturer from China

We are a China-based metal forming manufacturer specializing in metal spinning for custom and application-driven components.

With over 15 years of hands-on manufacturing experience, we support engineering and sourcing teams in producing metal parts where geometry, consistency, and forming reliability are critical.

Our core process is metal spinning, supported by complementary metal fabrication capabilities including roll forming and welding, CNC machining, and surface finishing.This integrated approach allows us to control forming risk, dimensional consistency, and delivery reliability across different project stages—from prototypes to low and medium volume production.

Metal spinning is selected when traditional stamping or deep drawing becomes high-risk due to large diameter, thickness variation, or tooling constraints.

Our metal formed components are widely used in:

• Building ventilation systems and air vents

• HVAC and heating equipment

• Aerospace and aviation-related components

• Automotive structural and functional parts

• Lighting reflectors and housings

• Telecommunication equipment enclosures

• Snare drum shells and musical instrument components

Buyers often evaluate metal forming suppliers based on process suitability, dimensional control, and long-term production stability.

By focusing on metal spinning as a controlled forming process rather than a generic fabrication method, we help customers make informed decisions before committing to tooling or large-scale production.

Metal Forming Solutions Built Around Metal Spinning

Metal Spinning (Core Process)

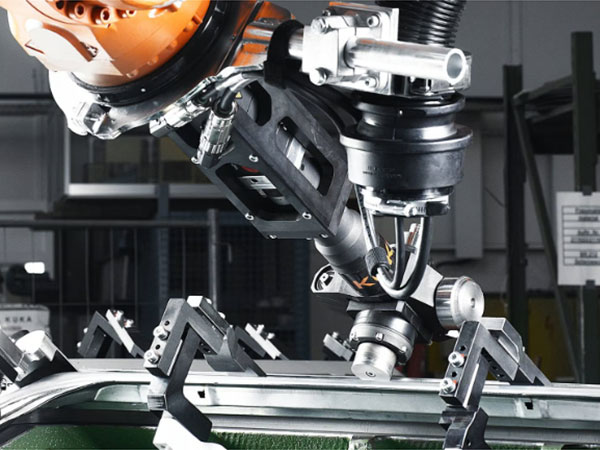

Metal spinning is our core forming process, selected for large-diameter, complex, or high-risk components where stamping or deep drawing becomes impractical.

It allows controlled material flow, flexible tooling, and reliable geometry across prototypes and production.

Metal Stamping (Supporting Process)

Used when part geometry and volume justify dedicated tooling, often combined with spinning for hybrid components.

Deep Drawing (Application-Dependent)

Applied selectively for symmetrical parts with stable wall thickness, evaluated case by case against spinning feasibility.

Drilling & Hole Processing

Secondary operations for functional holes, mounting points, and assembly requirements.

Cutting & Trimming

Used for edge trimming, profile definition, and preparation for welding or assembly.

CNC Machining

Post-forming machining for precision features, interfaces, and tolerance-critical areas.

Custom Metal Spinning for Large & Complex Components

We have high precision CNC spinning machine, manual spinning machine, punching machine, surface treatment and other perfect supporting equipment, undertake various products customization.

Why 500+ Customers Choose Us

Metal Forming Company FAQ

What Our Clients Say About Us

Our Partner

From the first time we provided the drawing of the product, we kept changing the design, JSSPIN’s engineers always actively cooperated and gave us professional advice to help achieve the product effect we wanted, and finally the finished product was produced to our great satisfaction, which is a professional metal manufacturer with strong R&D capability and trustworthy.

We have been cooperating for many years, JSSPIN is our lampshade metal housing supplier, its product quality is good, on-time delivery, sufficient capacity, especially for urgent orders to deal with timely, high cooperation, it has become our long-term and stable partner.

We are glad to work with JSSPIN, the goods are delivered in time, especially in shipping arrangement, providing us good advice to ensure we receive the goods in time and save the shipping cost, it is a very sincere supplier.

Client Visiting